This site is also available on:

Deutsch

Introduction to complex aircraft maintenance at Air Astana

The aviation industry places the highest value on safety and reliability, which is why regular maintenance of commercial aircraft is essential. Comprehensive inspection measures, such as the six-year C-check and the twelve-year C-check, are essential to ensuring the operational capability and safety of modern aircraft. For the first time, the Air Astana Group performed these two demanding maintenance cycles simultaneously at its maintenance center in Astana. The maintenance focused on aircraft of the Airbus A320 family, specifically an Airbus A321neo and an Airbus A320neo. This premiere not only represents a milestone for the company but also underscores the Air Astana Group’s high commitment to quality and safety in the field of aircraft maintenance and technical aircraft support.

The complexity of such maintenance can hardly be overestimated, as they go beyond mere inspections and involve the complete disassembly of the aircraft. This requires not only in-depth technical understanding and excellent specialist personnel, but also compliance with the strictest international safety standards. Furthermore, the extensive maintenance work is followed by responsible test flights to ensure that the aircraft has regained its full functionality. The following text delves deeper into the process, significance, and challenges of these special C-checks, while also highlighting Air Astana’s contribution to maintenance excellence.

Meaning and content of C-checks in civil aviation

The maintenance of commercial aircraft is divided into different inspection intervals, of which the C-check is considered one of the most intensive. A six-year C-check is a routine, yet highly detailed, maintenance check, often referred to as a “Heavy Maintenance Visit” (HMV). During this inspection, numerous systems are checked, wear parts are replaced, and the aircraft undergoes a thorough assessment. The focus is on both the mechanical integrity and functionality of the aircraft components. The goal is to identify potential defects early, before they could compromise flight safety.

The twelve-year C-Check goes significantly further: In addition to regular maintenance, it focuses on extended inspections of the aircraft fuselage and structural components. This examination can identify signs of material fatigue or incipient corrosion damage, which, if left undetected for an extended period, could have serious consequences. Therefore, this check also includes structural tests, detailed ultrasound measurements, and the disassembly of certain components for refurbishment or replacement. The necessity of such extensive maintenance is not only required for safety reasons; it also contributes significantly to the efficiency and reliability of aircraft in scheduled service.

From a technical aircraft maintenance perspective, C-checks are challenging tasks that require a high degree of coordination between specialist departments. These include mechanical maintenance, the inspection of electrical systems, and the certification and documentation of the work. Only through this comprehensive approach can it be ensured that the aircraft is optimally equipped for flight operations after a complete overhaul.

Technical expertise and infrastructure at Air Astana

The execution and success of such C-checks depend on highly trained personnel and suitable facilities. The Air Astana Group has laid a solid foundation at its maintenance centers in Astana and Almaty to meet the increasing demands of modern aircraft fleets. Since 2019, the company has already successfully completed 42 C-checks – a testament to its existing technical expertise.

The latest project, the parallel performance of six- and twelve-year C-checks, requires careful planning and the deployment of highly qualified technicians, engineers, and inspectors. These personnel must be familiar with the latest methods to safely implement complex diagnostic procedures and maintenance measures. Compliance with internationally recognized aviation standards and guidelines, such as those of the EASA or the FAA, is also crucial to guarantee flawless results.

Infrastructure also plays a key role: The maintenance hangars are equipped with state-of-the-art technology that not only enables efficient disassembly and assembly, but also allows for precise component analysis. This includes computer-assisted testing systems, high-resolution ultrasound equipment, and dedicated painting and corrosion protection areas. This equipment is essential for meeting the strict aircraft safety and quality requirements that are part of the agenda for a twelve-year C-check.

Insights into the first parallel six- and twelve-year C-checks

The simultaneous maintenance of an Airbus A321neo for Air Astana and an Airbus A320neo for FlyArystan marks a technological advancement and an organizational achievement for the Air Astana Group. Both aircraft are members of the modern Airbus A320 family, currently among the world’s most popular and efficient medium-haul jets. This chosen combination demonstrates the versatility and technical expertise of the maintenance team.

The six-year C-check for the A321neo was well prepared and included a comprehensive inspection of the engines, control surfaces, landing gear, and cabin systems. Disassembly involved not only the careful removal of large attachments but also the detection of invisible material fatigue or technical defects. After the repair and maintenance work was completed, a comprehensive test program was carried out to reconfirm the flight characteristics.

At the same time, the twelve-year C-check for the A320neo presented an even more demanding challenge. Specialized testing procedures were used to uncover potential structural weaknesses. Every part showing signs of wear was thoroughly examined and, where necessary, restored or replaced. Thanks to the high technical level and discipline of the maintenance team, these complex tasks were successfully completed.

Managing these two maintenance projects simultaneously required precise time and resource management—from spare parts and equipment utilization to staff scheduling. The fact that the work proceeded smoothly speaks volumes about the professionalism and organization of Air Astana’s maintenance units.

Conclusion

The first simultaneous performance of a six-year C-check and a twelve-year C-check in the Air Astana Group exemplifies the importance of meticulous aircraft maintenance in modern aviation. The demanding maintenance work included not only the complete disassembly and testing of complex aircraft systems, but also compliance with international standards, which are essential due to safety requirements. It demonstrates the high level of expertise of the technical staff and the outstanding equipment of the maintenance centers in Astana and Almaty.

The Air Astana Group has thus demonstrated sustainability and reliability in its maintenance management and strengthened its position as a responsible and safety-oriented player in the international aviation market. Furthermore, the technical support of aircraft such as the Airbus A321neo and A320neo was another important step in ensuring long-term, high-quality flight operations. Pilot projects and innovations such as these contribute significantly to the further development of the aviation industry and help guarantee the highest level of flight safety.

Consistent implementation of demanding maintenance specifications and a focus on technical expertise not only ensures safe flight operations today, but also safeguards the future viability of the aircraft. This impressively demonstrates how maintenance processes form the basis for technical reliability and customer satisfaction, which is of fundamental importance for airlines like Air Astana.

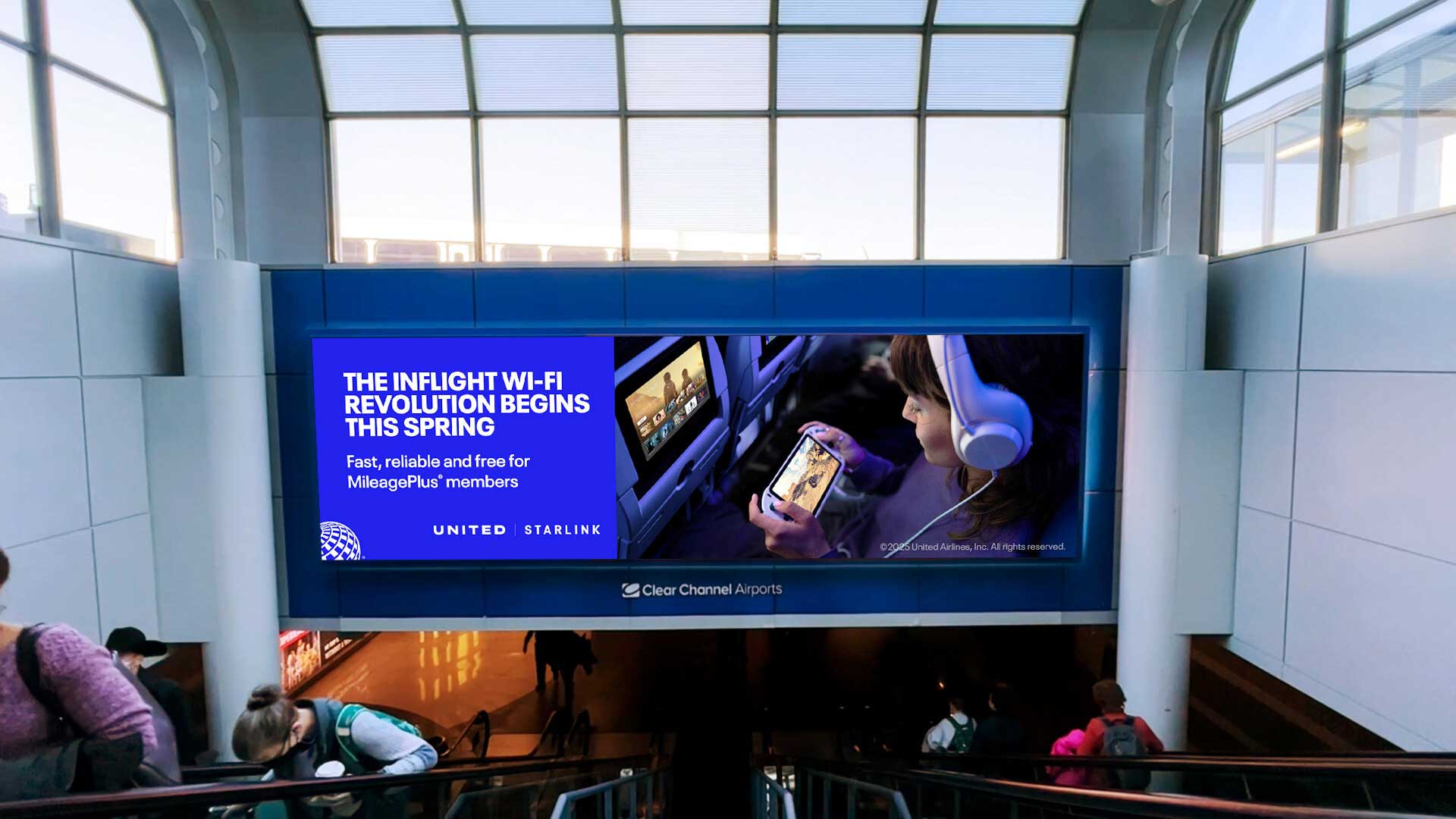

United Airlines brings Starlink internet on board (United Airlines brings Starlink internet on board)

United Airlines brings Starlink internet on board (United Airlines brings Starlink internet on board) UAC Karlsruhe: DFS communications system is being upgraded (UAC Karlsruhe: DFS communications system is being upgraded)

UAC Karlsruhe: DFS communications system is being upgraded (UAC Karlsruhe: DFS communications system is being upgraded) Starlink Wi-Fi on United Airlines: Revolutionary Internet connection on board (Starlink Wi-Fi on United Airlines: Revolutionary Internet connection on board)

Starlink Wi-Fi on United Airlines: Revolutionary Internet connection on board (Starlink Wi-Fi on United Airlines: Revolutionary Internet connection on board) Munich Airport ready for winter service (Munich Airport ready for winter service)

Munich Airport ready for winter service (Munich Airport ready for winter service) Lufthansa integrates Apple AirTag for baggage tracking (Lufthansa integrates Apple AirTag for baggage tracking)

Lufthansa integrates Apple AirTag for baggage tracking (Lufthansa integrates Apple AirTag for baggage tracking) KLM integrates safer luggage tracking via Apple AirTag (KLM integrates safer luggage tracking via Apple AirTag)

KLM integrates safer luggage tracking via Apple AirTag (KLM integrates safer luggage tracking via Apple AirTag)